Principle of activated carbon filter

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2020-12-24 10:59

- Views:

Principle of activated carbon filter

(Summary description)During use, the resistance of the activated carbon filter remains unchanged, but the weight will increase. Experienced professional staff can estimate the service life of the filter based on the weight change. The upstream and downstream of the activated carbon filter should have a good dust filter, and its efficiency specification should not be lower than F7. The upstream filter prevents dust from clogging the activated carbon material; the downstream filter blocks the dust generated by the activated carbon itself.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2020-12-24 10:59

- Views:

1. Hit-stick

The dust particles in the air move inertially with the airflow, or move irregularly, or move under the action of a certain field force. When a moving particle hits an obstacle, the gravitational force between the particle and the surface of the obstacle makes it stick to the obstacle

2. Fiber filter material

The filter material should be able to effectively intercept dust particles without forming excessive resistance to the airflow. Non-woven fiber materials and special paper meet this requirement. The messy and intertwined fibers form countless barriers to particles, and the wide space between the fibers allows the airflow to pass smoothly.

3. Inertial collision and diffusion collision

The efficiency varies with the size of the dust particles. The ratio of the amount of dust collected by the filter to the amount of dust in the unfiltered air is the "filtration efficiency". Particles smaller than 0.1mm (micrometers) are mainly used for diffusion motion. The smaller the particles, the higher the efficiency; the particles larger than 0.5mm are mainly used for inertial motion. The larger the particles, the higher the efficiency. Between 0.1mm and 0.5mm, the efficiency has a lowest point.

4. Resistance

The negative airflow of the fiber detours and produces a small resistance. The sum of the resistance of countless fibers is the resistance of the filter. The filter resistance increases with the increase of air flow. By increasing the area of the filter material, the relative wind speed through the filter material can be reduced to reduce the filter resistance.

5. Dynamic performance

The captured dust creates additional resistance to the airflow, so the resistance of the filter in use gradually increases. The trapped dust forms a new obstacle, so the filtration efficiency is slightly improved. Most of the captured dust gathers on the windward surface of the filter material. The larger the filter area, the more dust it can hold, and the longer the filter life.

6. Static electricity

If the filter material is charged with static electricity or the dust is charged with static electricity, the filtering effect can be significantly improved. The reason: static electricity causes dust to change its trajectory and hit obstacles, and electrostatic force participates in the sticking work.

Selection of activated carbon filter

The main factors that affect the adsorption effect and service life of activated carbon filters are: the type and concentration of pollutants, the residence time of the airflow in the filter material, and the temperature and humidity of the air.

In actual selection, the type of filter and the type of activated carbon should be determined according to conditions such as the type of pollutant, the concentration and the air volume of the treatment.

The capacity of the filter can be roughly estimated by comparing the amount of activated carbon material in the filter. For example, a 610×610mm filter on the windward side contains 30kg of the most common granular activated carbon, and another so-called new high-tech product contains 2kg of activated carbon. The activated carbon of that new product may have a much larger unit adsorption capacity than granular carbon. But its service life is one tenth of that of ordinary particulate carbon filter.

By monitoring the changes in the concentration of pollutants before and after the filter, it can be determined whether the activated carbon should be replaced. However, there is no practical and convenient monitoring method in China. Therefore, users can only determine the service life of the activated carbon filter according to the specified period or experience.

During use, the resistance of the activated carbon filter remains unchanged, but the weight will increase. Experienced professional staff can estimate the service life of the filter based on the weight change. The upstream and downstream of the activated carbon filter should have a good dust filter, and its efficiency specification should not be lower than F7. The upstream filter prevents dust from clogging the activated carbon material; the downstream filter blocks the dust generated by the activated carbon itself.

Related Information

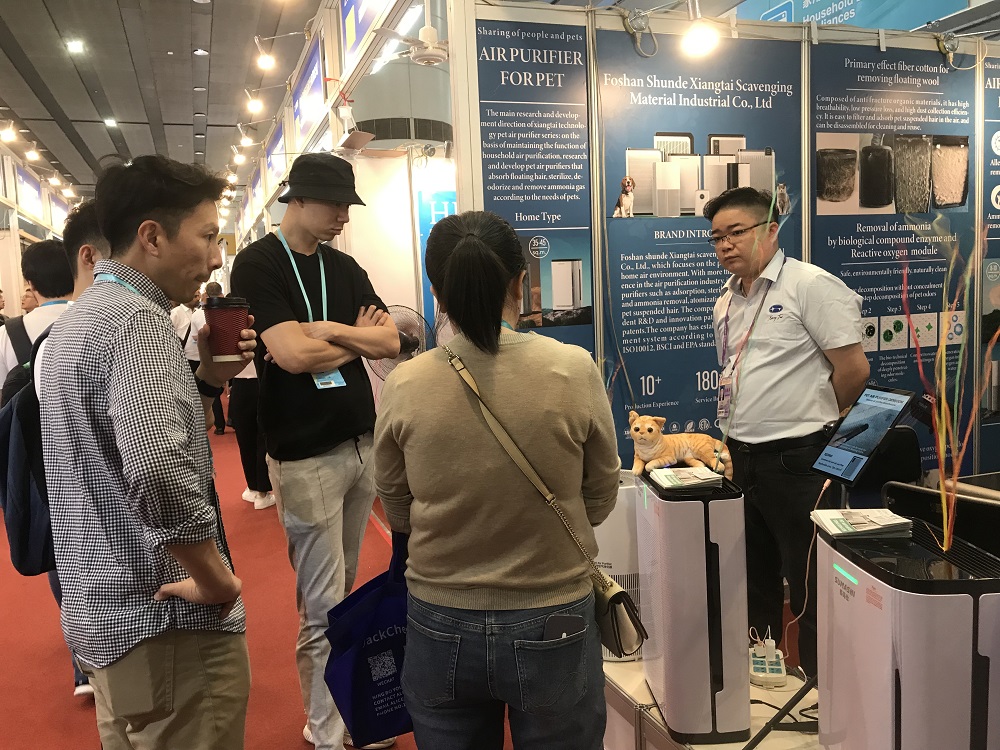

Foshan Shunde Xiangtai Scavenging Material Industrial Co.,LTD.

Add:Block 1, No.9 Industrial Road Fengjian Industrial Zone,Xingtan Town, Shunde District, Foshan City, China

Phone:18666556820 18124810081

E-mail:manager@cheuktai.com sales01@cheuktai.com

All rights reserved:Foshan Shunde Xiangtai Scavenging Material Industrial Co.,LTD. 粤ICP备2020089710号 Support: www.300.cn